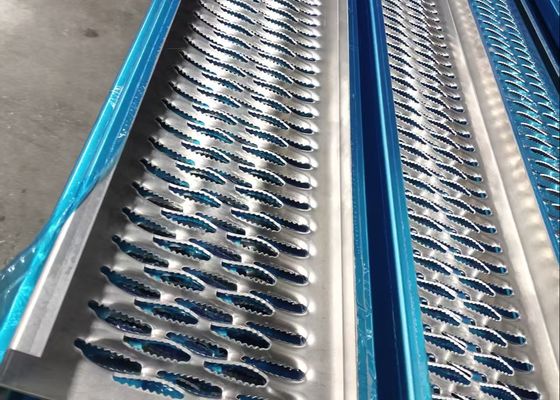

3-, 4- and 5-Diamond Grip Strut Safety Grating 3-Diamond Plank

Product Description

Grip Strut Safety Grating 5-Diamond Plank (2-1/2" Depth, 12 Gauge, 11-3/4" Width) - 52512 Galvanized

Serrated Grip Strut Grating

Standard Serrated Surface offers excellent slip resistance wherever maximum safety underfoot is essential. Material meets anti-slip values set forth in Federal Specification RR-G-1602A.

Non-Serrated Grip Strut Grating

For all-purpose use where a high degree of slip resistance is required plus a smoother texture and design. Product is non-stock and subject to extended lead time.

Proof of Performance

Tested by an independent laboratory for slip resistance according to standards and methods established by Federal Specification RR-G-1602D, GRIP STRUT® Safety Grating proved its superiority by exceeding all requirements.

The standards were exacting – five shoe sole materials tested in three directions under five conditions: dry, greasy, muddy, soapy and icy. GRIP STRUT® Safety Grating tested 10% to 180% more slip-resistant than similar materials, depending on shoe materials and surface conditions.

Fewer accidents, with resultant lower insurance costs and reduced workman's compensation losses, should be the logical reason for specifying GRIP STRUT® Safety Grating for walking-working surfaces and stair treads.

Specifications

Implementation Standards

- GB: GB13296-97, GB/T14976-2002, GB/T14975-2002

- American Standard: ASTM A312/A312M, ASTM A213/A213M, ASTM A269/A269M

- German standard: DIN 2462

- Japanese standard: JIS G3463

- Other standards: can be produced according to customer's standard

Product Dimensions

| Diamond Pattern |

Width |

Channel Depth |

Galvanized |

Aluminum |

| 2 Diamonds |

9-1/4" |

2" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 2 Diamonds |

9-1/4" |

2-1/2" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 2 Diamonds |

9-1/4" |

3" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 2 Diamonds |

9-1/4" |

4" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 3 Diamonds |

13-3/4" |

2" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 3 Diamonds |

13-3/4" |

2-1/2" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 3 Diamonds |

13-3/4" |

3" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 3 Diamonds |

13-3/4" |

4" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 5 Diamonds |

23-1/4" |

2" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 5 Diamonds |

23-1/4" |

2-1/2" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 5 Diamonds |

23-1/4" |

3" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

| 5 Diamonds |

23-1/4" |

4" |

11 Ga., 10 Ga., 9Ga. |

12 Ga. (.080"), 10 Ga. (.100") |

Applications

Grip Strut Plank can be made out of iron plate, aluminium plate or stainless steel plate, etc, based upon different working environments. If iron plate is used, when grip strut plank is ready, it can be electro-galvanized, hot dip galvanized or spray-painted.

Grip strut plank has nicer skid resistance and beautiful look, so it is widely used as stair tread, walkway and workshop floor in factories and transportation facilities, etc. When grip strut plank is covered with mud, ice, snow, grease, oily soil or cleaning media, grip strut plank can efficiently safeguard the safety of operating personnel.

Characteristics

- With non-slip, anti-rust, anti-corrosion, durable features and beautiful appearance

- Punching hole type with raised herring bone, raised crosswise, round, crocodilelips type, tear-type

- These hole types are all CNC punching holes

Advantages

- Economical to install with low material cost and nominal erection cost

- Standard mill-galvanized finish resists corrosion for lasting surfaces

- High-strength aluminum and Types 304 and 316L stainless steel provide maximum corrosion resistance

- Black unpainted steel available for installations requiring hot dipped galvanized finish after fabrication

- Light weight yet strong panels permit substantial reduction in structural steel requirements

Feature Advance

- Low cost - zinc plate is cheaper compared to after hot dipped galvanized

- Easy install - but need to consider carrying capacity

- Best anti-skid effect - 14 teeth around one hole grip shoe soles securely

- Low maintenance cost

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!